Litho Printing v Digital Printing

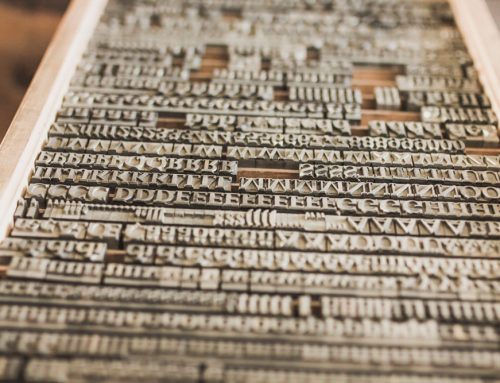

Digital print has been gaining ground regarding market share and customer choice and is now at the point where it will arguably become the dominant technology in the industry. Let me begin by giving a brief definition of both Lithography and Digital Print so as to draw clear distinctions between them. Lithography is the traditional method of printing. In ‘offset` printing the desired print image is burned onto a plate and is then offset to a rubber blanket and on to the printing surface. This process effectively ‘presses` ink onto paper. Litho printing produces products of excellent image quality and the colours will be a perfect match to anything from the ‘Pantone` reference guide. This quality will be consistent throughout the entire ‘print run`.

In contrast, Digital Print is usually a product of ‘toner` based machines and the process is very similar to standard photocopiers. However, digital presses are a lot more sophisticated in this day and age with advanced R & D development leading to impressive improvements regarding speed and quality. The direct connection to a p.c. allows jobs to be sent electronically and with perfect ‘proof` accuracy. Basically, a digital ‘proof` will be an exact replica of the job.

Litho Machine manufacturers have responded to the threat of digital by modernising the setting up process on new machines, this has improved set-up times for jobs and made them less complicated. However, the digital technology has also been improving and quality, as well as speed, have been the battleground between the two methods and continue to be so. An indication of the improvements in digital print is that in 1998 a typical digital machine was capable of producing five copies a minute. Today’s Digital Presses are capable of at least eighty prints per minute. It is customer demand that drives this competition within the industry. Business regularly demands presentation materials within 24 hours, the 3-4 day wait for a litho job is simply too long for some customers want fast turnaround same day or next day completion.

There is one key benefit for customers who will require a long-run job and are willing to accept the delay that comes with litho production. Once a deal is reached for a digital print run the price per unit is unlikely to decrease in tandem with more demand. This is because the manufacture price will not change; it costs the same for the printer to produce 100,000 copies as it does 10,000 copies price per unit. However, due to the ‘up front` costs which are far more substantial for a litho job, if the customer decides to increase the order after completion of the first batch, they are likely to be able to negotiate a discount on the price per unit. This is because of the ‘economy of scale` that exists within the litho print industry, the longer the run the lower the price per unit for the manufacturer. It allows flexibility in pricing for litho printers.

The competitive advantages for digital print are without doubt speed and cost. Customers can have ‘print on demand` when it comes to digital print. This is very beneficial for small quantities. When it comes to litho print, whether you want one hundred or one million copies, the upfront set up costs are the same, this is why printers have minimum quantity orders when negotiating with customers regarding litho. When it comes to digital, a customer can place an order for just 20 copies as any quantity is acceptable to most print businesses. Another advantage for digital, as well as no ‘set up time` requirement, there is no drying time, upon completion the job can go directly to finishing for lamination, binding and delivery.

Variable data is an area where digital also has a key competitive advantage. When printed digitally, the customer can edit the text at any time, the same applies to images. This means that any job can be personalised in a way that litho cannot. Imagine the amount of ‘plates` that would be required if data was being continually changed for a litho run.

There is greater paper stock flexibility that benefits litho printing machines. Litho presses can print onto just about any type of paper and this is because there is virtually no heat generated from the process. In contrast, digital printers are at a disadvantage and can only use more expensive, specially designed paper that will not crack and bake due to the heat generated from a digital printing machine. However, technological improvements have led to new type of plasticised paper that can withstand the heat damage. On balance though, litho printing has the advantage and paper stock flexibility is worthwhile to most print business manufacturers.

While it is true that ‘proof accuracy` is an exact replica of the finished job for any digital print order and this cannot be matched by litho, there are quality advantages regarding colour and detail that make litho print productivity advantageous especially when you consider the sheer volume of quality print copies as litho press can produce once up and running. The artwork requirements are basically the same for either method a PDF that the customer supplies to the manufacturer.

In summary, the digital press suppliers will continue to attack the market in the coming years. Technological advances will attempt to address the ‘heat` problem and attempt to make Digital Presses compatible with all stock, there will also be attempts to improve the colour and quality capabilities that have hampered progress. For now though, especially regarding longer run jobs where the wait time for completion and delivery is acceptable to the customer, Litho is still King.

What great content I really appreciate the content because it is very informative.

These are some very unique printing ideas that I have ever come across, thank you so much for sharing such valuable information with us, will surely pass this ahead with my other friends as well.